What is the hydro pool installation process?

Posted on 30 April 2024 By Michael Wood

In This Article

What does a hydro pool installation look like? From detoxification to relaxation, the benefits of hydrotherapy pools are endless, becoming…

What does a hydro pool installation look like?

From detoxification to relaxation, the benefits of hydrotherapy pools are endless, becoming increasingly popular in new build hospitals, rehabilitation centres and individual’s homes.

However, installing a hydro pool requires expertise and precision to ensure your facility meet your needs and suits your environment.

To help give you an insight into what the process of installation involves, we’ve put together a step-by-step guide, highlighting the important stages from design right through to the pool handover.

Jump Straight To –

- Hydrotherapy Pool Design

- Hydrotherapy Pool Construction

- Hydro Pool Installation

- Hydrotherapy Pool Plant Room

- Safety

- Pool Fill Up and Commissioning

- Training and Handover

- Innova Hydro Pool Installation Video

Hydrotherapy Pool Design

Anything to do with a hydro pool installation should start with a design consultation meeting. With Innova, this will typically involve the Project Consultant, CAD Engineer, Hydrotherapy Pool Designer and Project Manager, who will discuss with you will what is needed in the pool itself, including size and materials based on the needs of the project.

Other considerations include how many people will be in the pool, helping to determine the size of pool required, and additional features like water jets, lights, whirlpools and wave systems.

Depending on whether then pool will be going into a domestic or multi-user environment, there will also be discussions about the best options on whether or not the pool will be above or below ground.

Following these preliminary talks, the CAD teams will then create detailed layouts of the pool shell, including required fittings, estimated pipe work and the initial pool schematic.

Once the primary design proposal has been received and approved by you, the CAD Engineer will create 3D designs of the pool shell, HVAC design and plant room, ready to be reviewed for final approval before work can start on the construction phase.

CAD teams create detailed layouts of the pool shell, including required fittings, estimated pipe work and the initial pool schematic.

Hydrotherapy Pool Construction

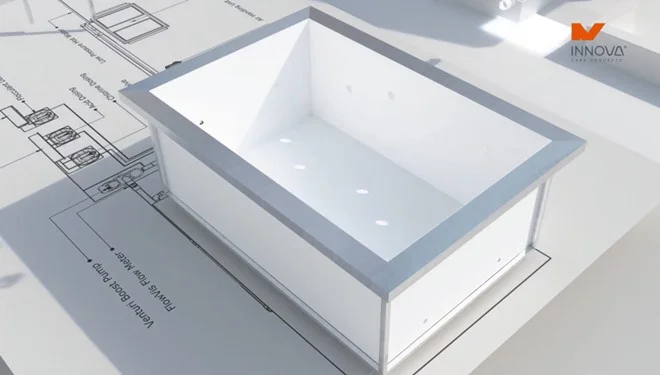

When it comes to hydro pool installation with stainless steel, the pool shell will often come in one piece, and will require more space to be lifted into place.

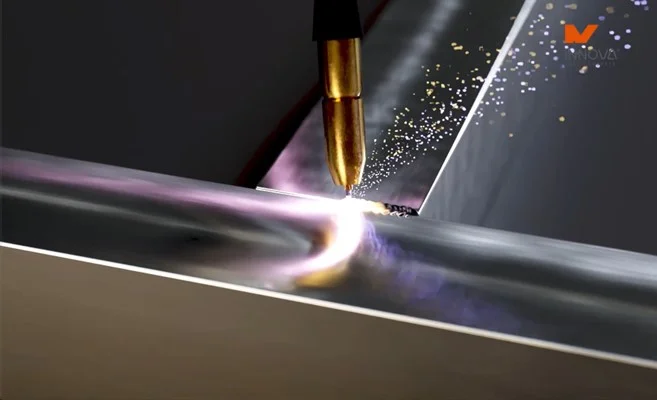

Larger pools will come in two pieces, and will be welded together when in place. If the pool is going in the ground itself, there should be a dug-out area with a concrete base that it will sit in.

Once the shell has been fabricated, the population stage starts. This process involves suction and return fittings being attached, helping to circulate the water in the pool, whilst the pipework is installed that ensures efficient filtration.

Energy efficient LED lights are then fixed to the pool shell, helping aid sensory stimulation during aquatic physiotherapy.

With the fittings and fixtures in place, the water testing process can begin, testing the shell for any leaks and ensure it is watertight prior to delivery.

With larger hydro pool installations with stainless steel, the pool shell will often come in two pieces that are welded together.

Hydro Pool Installation

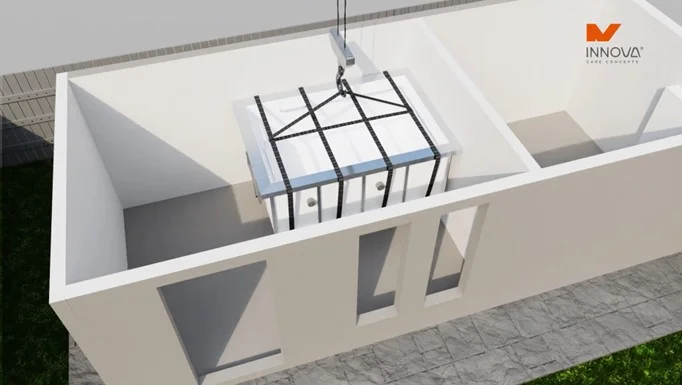

Delivering a hydro pool shell to site can be a tricky task. From loading the shell onto a lorry to navigating narrow lanes and craning a pool onto site, detailed and lengthy risk assessments need to be carried out by contractors and suppliers.

Before your pool is transported to site, the on-site preparation is carried out by the contractor, with the ground works completed to enable a concrete base to be laid down for the pool shell to sit on. With ground works in place and safety checks carried out, your pool can then be safely craned into position.

When the pool is sat in position, it is then covered and left alone right until the final stages of construction. Covering the pool allows workers to still use the space to build around the pool without damaging it.

Only when there are water and electrics on site will the hydrotherapy pool be plumbed in.

Plumbing around the pool will see pipes connected from the pool shell into the plant room, and HAVC duct work carried out in the pool hall.

With the pipes connected, pressure testing can start, where water is physically pushed through the pipes to test for leaks.

Hydrotherapy pool shell being safely craned into position.

Hydrotherapy Pool Plant Room

The plant room is the beating heart of any hydro pool, ensuring it functions correctly and manages the environment where your pool is housed.

Made up of several parts, experienced installers like Innova have the expertise to ensure your hydro pool installation has the correct equipment for your plant room.

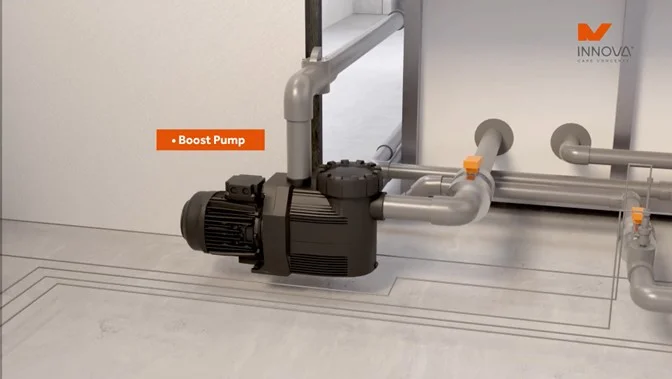

The first part of a plant room install is to fit pumps that circulate water, filters that maintain water clarity and dosing systems that help achieve the perfect chemical balance for the pool’s water.

Next, there is the control unit to be fitted, helping deliver the right type of climate and temperature for your pool and pool hall.

To help minimise regular manual intervention, a Besgo Valve and automatic water top are installed, helping automate the backwashing process of the pool’s filters to maintain optimal water flow and purity.

Learn more about hydrotherapy pool plant rooms.

A boost pump helps circulate water for your hydro pool.

Safety

Hydrotherapy pools often support individuals with complex needs so ensuring they have the correct safety equipment is a must.

A spill kit, eyewash station and health and safety kit should always be included as standard, helping you to manage any unexpected situations that should arise.

Pool Fill Up and Commissioning

Once your safety kit is in place and the plant room has been completed, technicians will carry out testing and commissioning.

Firstly, they will fill up the pool for water balancing tests.

With the pool filled up, they’ll then test the filtration system, making sure that the chemical levels, including chlorine and pH levels, are functioning perfectly to support your care requirements.

The final part of the commissioning process of a hydro pool installation is to carry out tests on the plant room, ensuring it is running at the desired parameters.

As part of the commissioning process, technicians will fill up your pool to carry out water balancing tests.

Training and Handover

Following the final tests and commissioning, your pool is now ready to handover.

To help keep your hydrotherapy pool in great condition, pool suppliers like Innova provide a comprehensive training programme, including a full handover service including demonstrations of how to operate the plant room equipment and daily maintenance/cleaning procedures.

In addition to face-to-face training, an O&M Manual is provided to activate your warranty with your supplier’s service team, as well as featuring detailed technical information to maintain your pool.

Innova Hydro Pool Installation Video

You’ve read through each of the key stages of a hydrotherapy pool install, but what does it actually look like?

We’ve brought the installation process to life with an animated video, highlighting each step.

Watch our video below to see how a hydro pool is brought to life.

Summary

Whether your hydro pool installation is for your home or going into a multi-user environment like an SEN School, working with an experienced supplier can make the process easier and less stressful.

From the initial design consultations through to the final handover, there is a huge amount of detail to go through to ensure your pool is suitable for your environment and meets your care needs.

To get the support you need to install a hydrotherapy pool, get in touch with one of our advisors by using the contact form below.

Speak to The Experts

Need assistance with product enquiries, general inquiries, or product support? Our Phonelines are open 9am - 5pm Monday to Friday

0113 519 0319

Or, fill out the form for a call back.