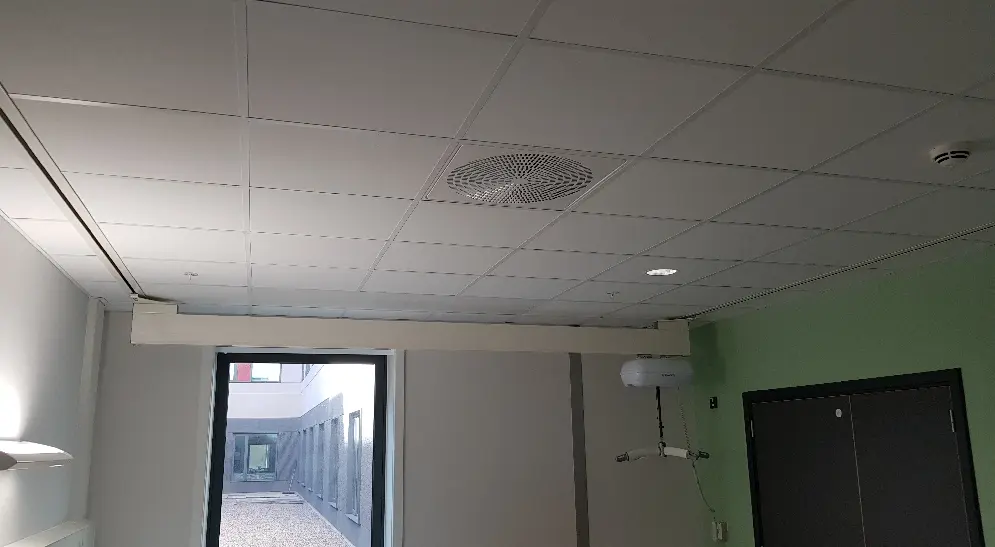

Ceiling Track Hoist Installation into Existing Wooden Ceiling Joists

Typical ceiling joists aren’t designed or supposed to facilitate heavy weights like overhead hoists are. A wooden joist must be at least 100mm x 100mm to be fixed directly into (for a 200kg system), and the coach bolt must fix directly into the centre of the joist.

The best way to fix ceiling track to timber joists is by using a metal Unistrut or load spreading beams of equal strength that span above the joists. However, to span joists with a Unistrut, you must be able to access the roof space above the room, and of course, the primary structure must be of sound construction.

Ceiling track hoist installation with Concrete Fixings

Installing ceiling track with concrete fixings can be a bit trickier. It is important to remember that the track cannot be installed straight into the suspended ceiling structure underneath the concrete soffit.

Putting any additional weight on these can be dangerous, and is likely to affect the structural soundness of the ceiling. Different kinds of concrete soffits may include:

- Hollow Slab

- Pre-stressed beam and block

- Reinforced concrete

- Pre-cast slab

- Pre-stressed slab

- Waffle slab and drop beams

- Profiled concrete deck

To fix into structures like these, we’d put a drop-in anchor into the concrete slab. A hole is drilled, and the anchor is placed inside the hole and then expands to fix itself in there permanently.

The M10 threaded rod then screws into this anchor and provides enough strength and stability to hang track from it. When fastening into a profiled concrete deck or beam floor, metal unistrut is used to span the channels or the beams so that fixings can be made in the correct locations.

Installing a Ceiling Hoist Directly Into Steels.

When installing ceiling tracking into steel beams, we either fasten M10 threaded rods drops directly into the beam, or we use metal Unistrut above or below the beam clamped with special brackets. There are many different profiles of metals beams that we can work with, however, we find that the ‘I’ beam offers the best fixing.

Ceiling track hoist installation with Lateral Bracing

We use a lateral brace (this can be used with all methods of fixings) if there’s a void of more than 200mm between our primary fixings and the finished ceiling. This prevents the threaded rod from moving side-to-side, which can cause severe damage and cracking of the plasterboard ceiling.

The brace is fitted at about a 45° angle to offer maximum support and stability to the rod.

Ceiling Hoist Load-Bearing Requirements

The amount that the hoist will be lifting is paramount when working out how the tracking will be fitted. We usually calculate the amount the track should support by multiplying the weight limit of the hoist unit by 1.5.

For example, if we are using an AirRise260 (with a 260kg weight limit), we calculate it as 260 x 1.5 = 390kg lifting allowance. This allows for the weight of the hoist unit itself, the track and a safety margin for accidental overloading of the unit.

We also use the weight limit of the hoist unit to determine the track fixing requirements. When the track is fitted to the ceiling, the rail should be fixed at even distances to ensure maximum stability.

There should be a minimum of 3 fixings on each rail when the track it is ceiling mounted (this is the same for track curves — they too require 3 fixings). The lower the weight limit of the hoist, the farther the fixings can be spread.

This also depends on the track profile/size. If the track is deeper, then it can accommodate more weight and the fixings can be further apart.

When working out the distance between fixings, we use this table:

| 65mm profile | 120mm profile | |

| 150kg weight limit | 2.8m between fixings | 6m between fixings |

| 200kg weight limit | 2.0m between fixings | 5m between fixings |

| 260kg weight limit | 1.5m between fixings | 4m between fixings |

Summary

This is a general guide to how ceiling track hoists are fitted in different buildings with different materials, but there is a range of ways and techniques used depending on the situation. Whilst we’ve touched on wooden joists, concrete, and steel fixings, there are other ways to install ceiling track hoists that may be more suitable.

If you’re still stuck for answers and need more information, then take a look at our Specifier’s Guide to Healthcare Environments.